Congratulations to Daniel, Deniz and Michelle for publishing their paper on “Inkjet printing of epitaxially connected nanocrystal superlattices”, for publication in Nano Research; check out the full paper here (doi: 10.1007/s12274-021-4022-7).

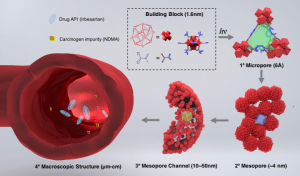

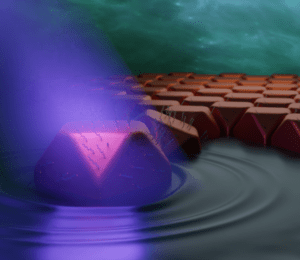

Creating and studying mesoscale materials formed via directed assembly of nanoscale building blocks presents myriad exciting scientific and technological challenges. Recent advances in mesocrystal superlattices formed by the directed assembly and epitaxial attachment of colloidal nanocrystal building blocks have opened new horizons to create novel materials with properties by design. The community has been particularly intrigued by theoretically predicted emerging properties such as Dirac-type electronic structure and phenomena like topologically protected spin-polarized states. However, to date, experimental validation of these emerging properties is still lacking, which is largely due to gaps in our understanding of and control over processing-structure-property relationships.

Bringing the prospects of mesocrystals to fruition is contingent not only access to high-quality nanomaterial building blocks, but also on advances in fabrication methods. The conventional route to create mesocrystals involves assembly and attachment of colloidal nanocrystals at the interface of an immiscible fluid. This process involves an intricate choreography of several physicochemical processes which has complicated the path towards high-fidelity mesocrystal superlattices. With an eye towards addressing these fabrication challenges, the results described in our enclosed manuscript establish the foundational processing-structure relationships of epitaxially connected PbSe nanocrystalsas a model system.We systematically examined the printing parameter space successfully demonstrated how inkjet printing of colloidal nanocrystal solutions on a sessile subphase droplet can create epitaxially connected mesocrytstals at sub-millimeter length scales. Beyond the specific system of PbSe-based mesocrysals, we anticipate that insights from this work will spur on future advances to enable more mechanistic insights into the assembly processes and new avenues to create high-fidelity superlattices.